AG Air Through Compact

The Air Through Compact is our universal heatsetting system, suitable for all types of felts and fabrics. Of the 60 systems ordered (January 2009) according to this concept, 21 are for forming fabrics, 17 for press felts and 22 for dryer fabrics.

The Air Through Compact is based on the throughflow principle: The heat transfer to a permeable surface increases significantly when a flow of air through the product is generated.

Further, the flow of air through the product leads to direct contact between the air and the fibers inside the fabric, increasing the heat transfer even more. The efficient heat transfer results in increased heatsetting capacity, as the product speed can be increased without reducing temperature in the product.

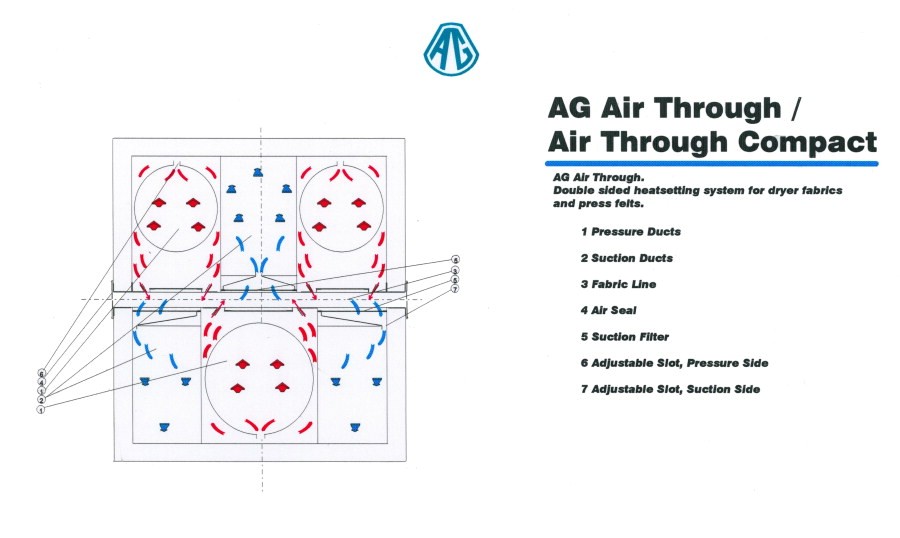

The figure shows a cross section of the Air Through Compact. The hot air exits from three pairs of inclined slots at high velocity. Between the slots, a part of the dynamic pressure of the air is transformed into static pressure. Because the pressure zone at one side of the fabric is faced by a return air zone on the opposite side, the pressure difference will set up a flow of air through the product.

Although the throughflow principle shows its superiority for high permeability fabrics, as dryer and forming fabrics, it is highly efficient for press felts as well. Our customers have reported that even dense pick-up felts are treated successfully in Air Through Compact systems.

Temperature profile documentation

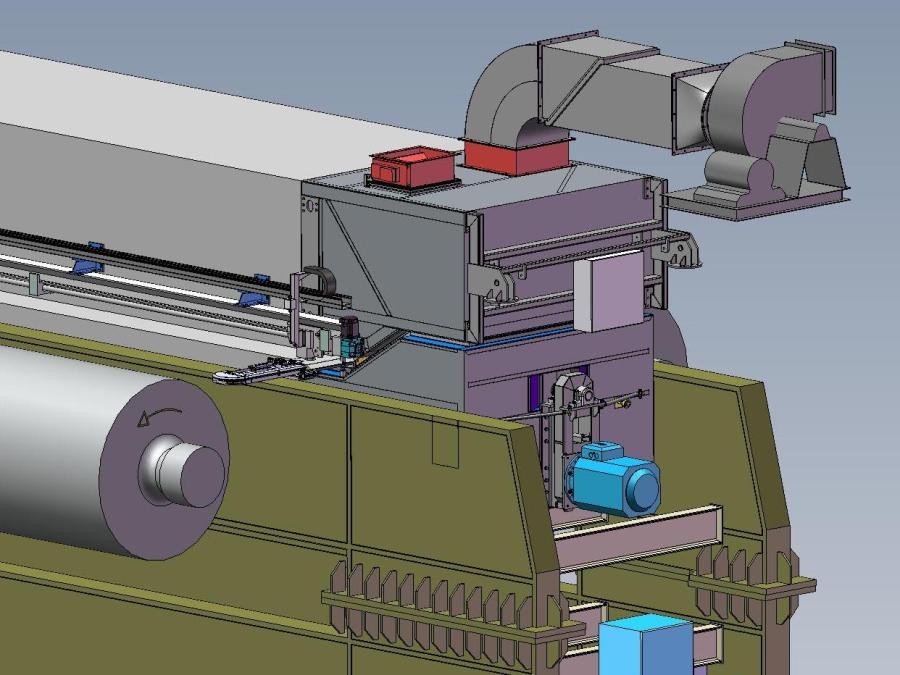

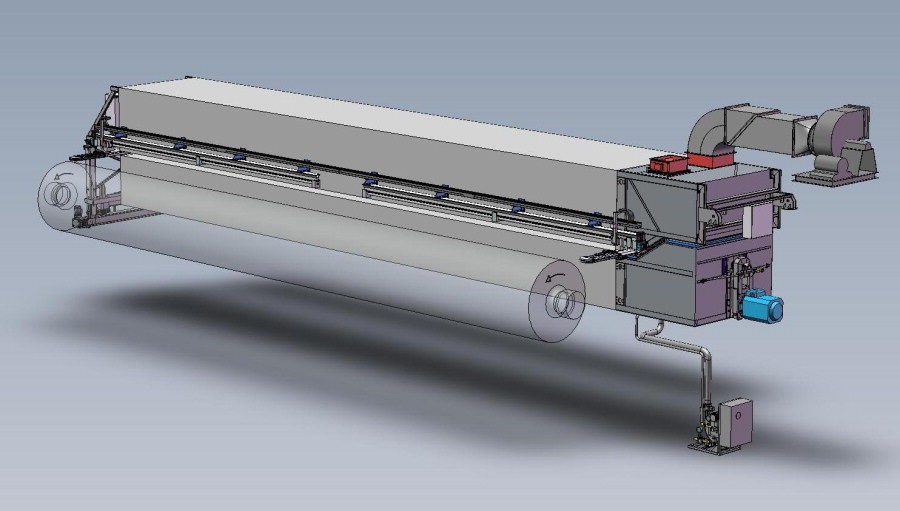

In an Air Through Compact, the heater and the circulation fan are placed in an extension of the two air boxes, in one end. The length of this extension, including the circulation fan motor, is just about 2.5 meters. In cantilevered machines, this will fit snugly between the cantilever beams in the rear side of the machine. This arrangement saves space, and reduces the heat consumption and heat-up time of the system.