AG Tenter 2x2

Traditionally, press felts have included one base fabric only. Modern felts, however, often include two or more bases. The bases can be heatset together, or separately, for later being combined before needling. The bases have different properties, that is, they may react differently to heat. If two bases are heatset together in a hot air heatsetting system to secure that they reach the same length, one may shrink more in the cross machine direction, pulling the other in such a manner that the latter may form wrinkles on the rolls. This may damage the fabrics.

Our AG Tenter 2x2 is designed to overcome this problem, tentering two fabrics simultaneously while allowing them to shrink differently under full cross machine tension control.

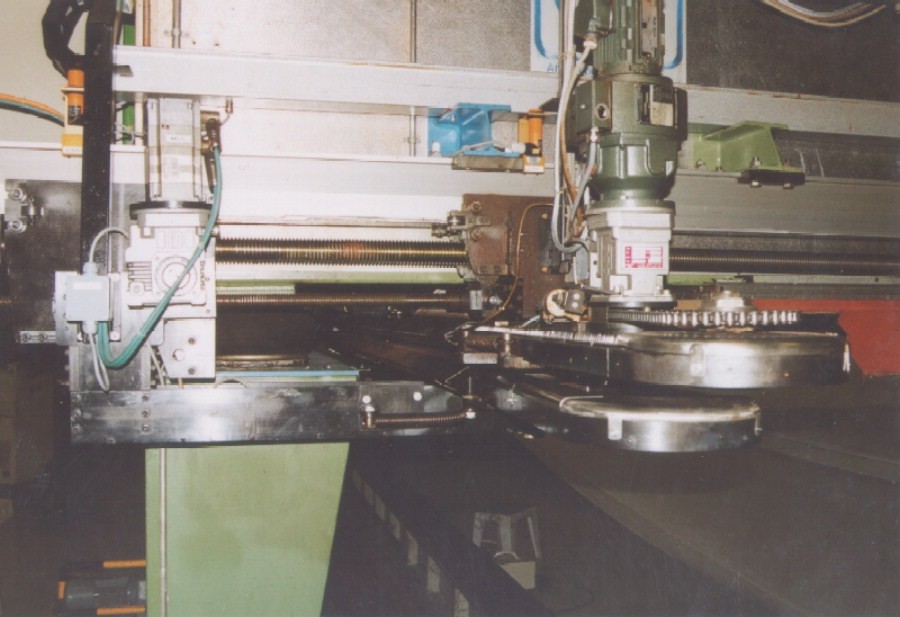

The photograph shows this double tenter system in operation, combined with an Air Through system. The relative cross machine direction movement of the tenter frames is achieved by a screw spindle connecting the frames, run by a servomotor. Load cells sense the forces in the fabrics and provide input signals to the servo systems, running the tenters in the cross machine direction. The lower photograph shows the screw spindle for the relative movement below the main spindle for moving both frames.

The system allows a relative movement of the frames up to about 500 mms in either direction.

We hold a patent on the AG Tenter 2x2 principle.