AG Tenter 2

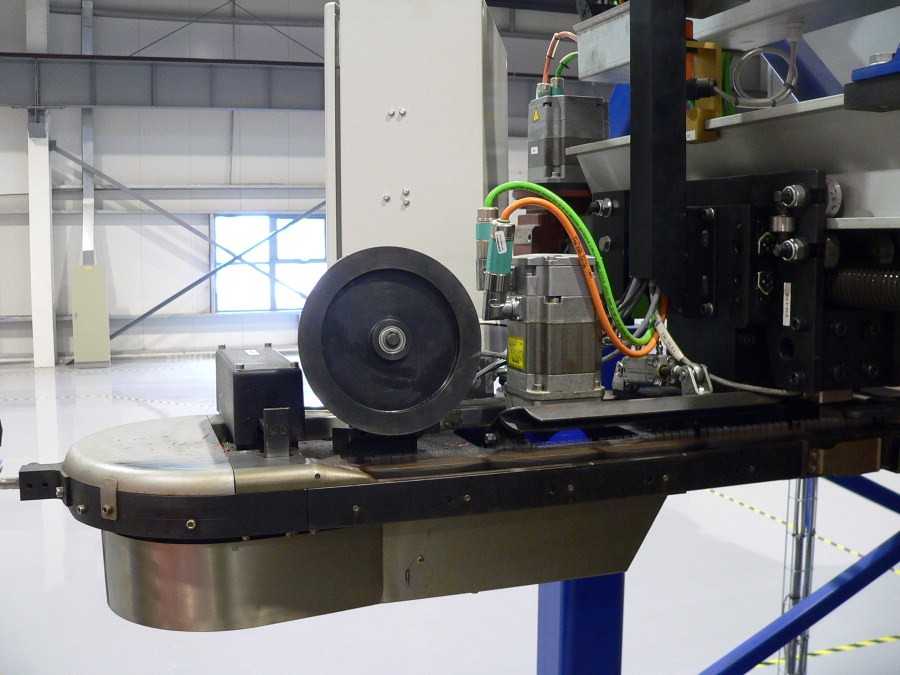

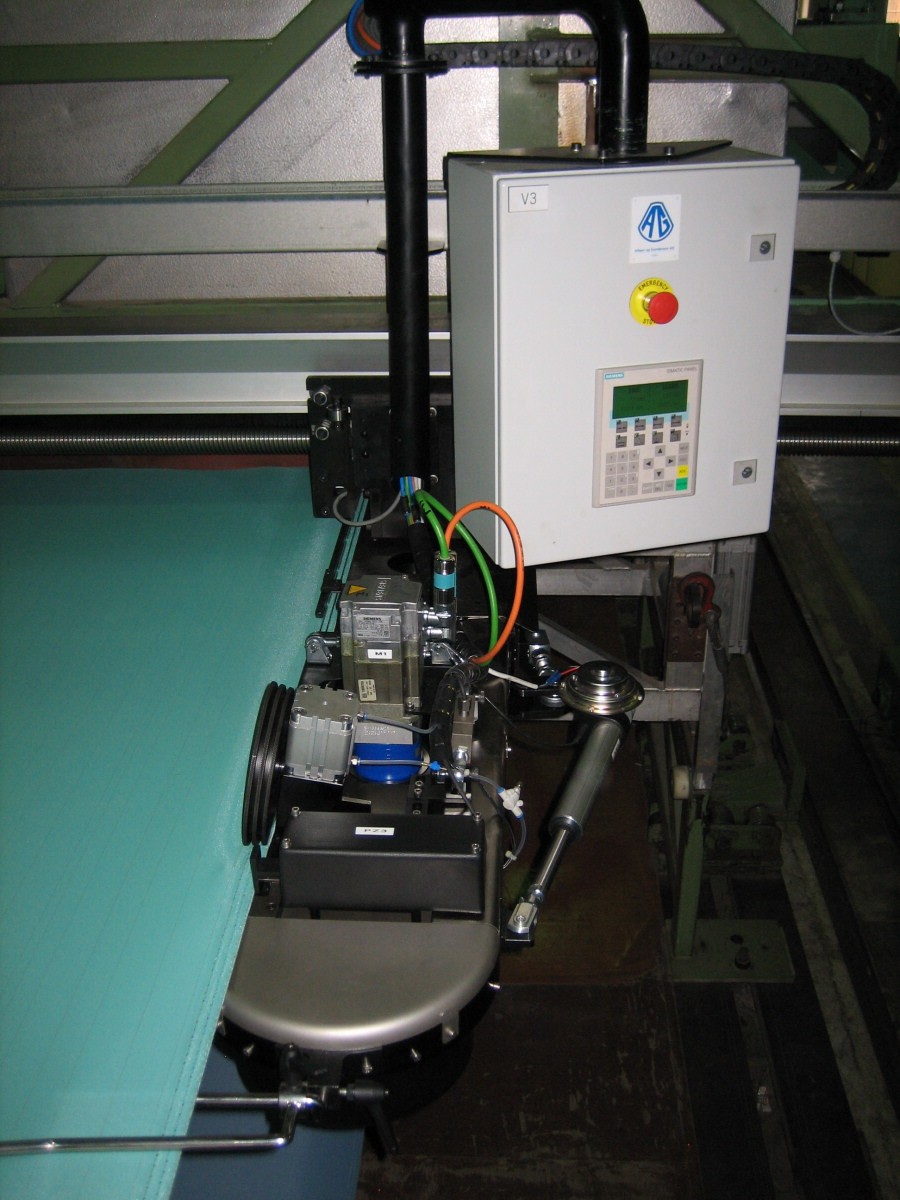

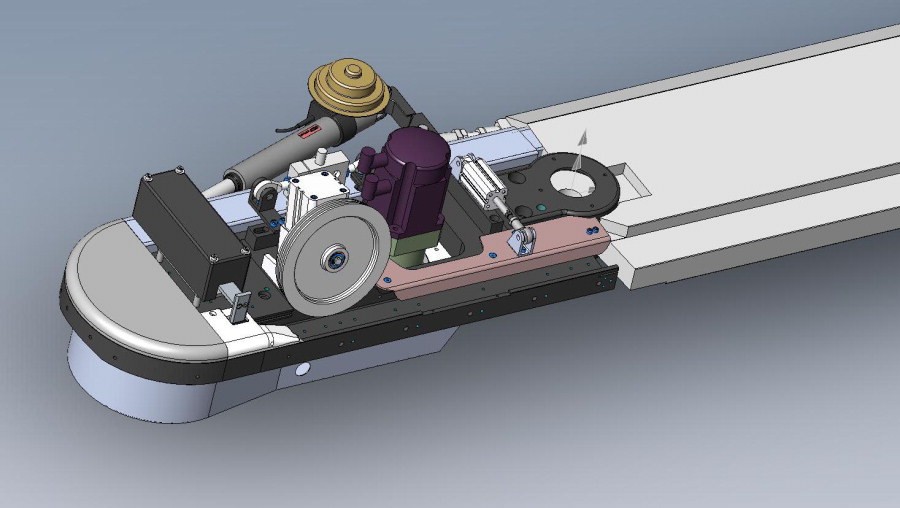

The AG Tenter 2 is a driven tenter. Non-driven tenters are likely to generate secondary bows close to the edges of the fabrics due to friction. The bow may, in extreme cases, extend almost one meter in from the edge, causing problems during seaming of that area. The patented drive system of our tenter is designed to overcome the friction, thus avoiding formation of the bow.

We hold a patent on the drive system of the AG Tenter 2 in several countries.

AG Tenter 2 is the only tenter available on the market today, which will transfer the drive force to the tenter elements along the full length of the heat zone. Other designs will lose the drive force to the tenter elements from where the fabric starts to stretch.

From there on, to the end of the tenter, the friction forces cannot be compensated. The weave pattern is most likely to be deformed at high temperature, so the last part of the heat zone is where the influence of friction forces should really be avoided.

The drive system of the AG Tenter is torque controlled. This means that, instead of controlling the speed of the tenter chain directly, it is controlled by controlling the drive force. In this manner, the tenter drive system is insensitive to fabric speed variations, which may be caused by problems in the drive system of the stretching machine.

- The tenter can be built for reversible operation if this is required.

- Normal design cross machine direction tension in the fabric is 7 kN/m

- (40 pli), but we can also provide a reinforced model, designed for 12 kN/m (67 pli).

Due to fabric shrinkage inside the heat zone, the local cross machine tension in the fabric may drop to zero over a certain length of the tenter. In that area, unintended unpinning of the fabric may happen, possibly causing loss of the fabric. This danger is eliminated by the installation of our fabric clamps, which fold down inside the pins.