Filters

Filters are the core of a well functioning air extraction system. The combination between innovation and well proven solutions make our filter systems synonymous with quality and secure operation. AG deliver filters for most industrial processes and offer tailor made solutions to fit each process and facility, as well as a wide variety of standardized solutions. By combination we can offer an optimal system at both the right efficiency and price.

Bag Filter

A bag filter consist of a number of textile bags placed in a given geometry. These filter particles from the contaminated off-gas. The filter size and quality of the filter media is adapted according to each process, temperature and experience attributes. Our filters are well suited for most processes, even where there are heavy dust loads, abrasive dust and high temperatures.

- Capacities from 5 000 - 1 000 000 m3/h (or more on request)

- Capturing HCL, SO2 and PAH

- Simple service solutions and maintenance

- Deliveries with weather protection for maintenance and bag change under all weather conditions

- Can be delivered with ATEX compliance

- Module based systems ensure quick and safe delivery and erection

- Filtrates most particle types

- Low emissions, normally < 5 mg/Nm3

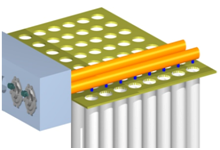

Cassette filter

The cassette filter works in the same way as a bag filter. The main difference are the filter elements and the mounting of these in the filter unit. The cassettes make completely differenent geometries of filter units available, ie. where the space is limited. The cassette filter is especially suited for indoor units and for the easier types of dust.

- Capacities from 2 000 to 100 000 m3/h per unit

- Can be delivered with weather protection which enables maintenance under all weather conditions

- Can be delivered as ATEX approved

- Module based delivery assures quick and safe erection

- Suited for most common dust types

- Low emission. Normally < 5 mg/Nm3

- Can be delivered with Sinter Compact elements

Cartridge filter

Cartridge filters make use of a crinkled filter media to attain a larger filtering area than a smooth surface. This enables a large filter surface contained in a small geometry.

Cartridge filters are usually used in applications with low amounts of air, fine particulates and dry dust.

- Capacities from 500 - 100 000m3/h

- Temperatures up to 100°C

- Low ratio of space-to-filter area

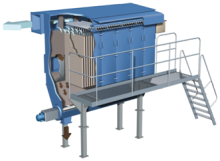

Electrostatic precipitator

The electrostatic precipitator(ESP) is well suited for many processes, especially those with large amounts of dust and high temperatures. The gas passes through ionisation electrodes before being gathered on the collector plates.

- Low pressure loss

- Simple and well proven system

- Can withstand high temperatures

- Can be delivered as wet precipitators (WESP)

- Low operating costs

Oil mist filter

AG carry extensive experience in removing oil mist and oil smoke from a variety of closed processes like CNC machines, and from open installations such as lathes, mills and saws. Our goal is finding the right solutions together with our customer to ensure optimal work conditions, increased productivity and reduced sickness absensce, while also fulfilling applicable environmental demands. Our solutions make for a separation of up to 99.99% of all particles >0.3µ, and thus the air can be brought back into the ventilated area.

Silofilter

AG carry silofilters in a variety of shapes and sizes. Our silofilters can be equipped as ATEX classified, and we also carry applicable silo equipment like pressure relief valves, level sensors, feeding equipment, loading bellows etc.

Spotfilter

The spot filters are often used on belt conveyors for on -off loading, where the dust can be dropped back into the process. Simple maintenance, small units and low investment costs are some benefits using a spot filter.

Insertion filters

These are filters that can be built into silos, conveyors etc. The insertion filters are low cost and space saving.